Introduction:

In our day-to-day life we came across various products and services, which contribute a significant value to our life. These products and services are delivered to us by means of the effective shipping operations.

This Shipping operations are made effective by means of various components. One of these components is “Corrugated Box”.

A Corrugated Box is cardboard box made up of paper pulp layers consisting an inner layer, middle layer and a outer layer, primarily used for packaging goods and materials.

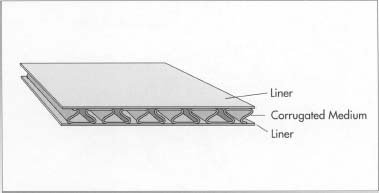

Structure and Composition:

Corrugated Box is primarily made up of three layers –

- Inner Layer –

- Middle layer (Fluted Layer) –

- Outer Layer –

Inner Layer –

The Inner Layer of a corrugated box is a flat paper sheet with adheres with the Fluted Layer with glue, which is starch base material.

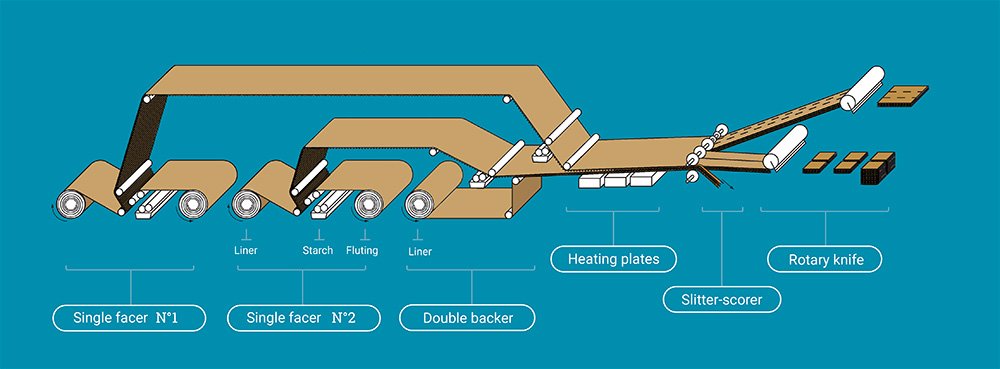

Middle Layer (Fluted Layer) –

The Middle layer of a corrugated box also called as Fluted layer. It is prepared by passing the paper sheet through the heating rollers and fluting rollers.

Outer Layer –

The outer liner of a corrugated box consists of a flat paper sheet which the glued over the fluted layer.

All these types of the flutes used in corrugated box making it suitable for providing excellent strength, cushioning and printing properties

Types of Flutes in Corrugated Boxes

There are various types of the corrugations (Flute types) used in the shipper preparation.

A Flute –

A Flute in a corrugated box is the original corrugated flute design and is the thickest. A Flutes provides great cushioning properties which is mainly used in fragile products providing it strength and protection from damage.

It contains the 33 Flutes per foot and the ¼ inch thick.

B Flute –

B Flute in Corrugated box has low arch height (Flute Height) and more flutes per foot as compared to A Flute. The higher flutes per foot and lower flute height contributes in more strength making it stiff and flat, also making it easy for printing and die cutting.

B-flute provides great resistance to punctures and crushing, and it also takes up less space in the warehouse.

B-flute, originally designed for package canned goods, also used in crafting beverage trays, creating wrap-around blanks, forming glass-to-glass packs, and manufacturing slipsheets.

It contains 47 flutes per foot and 1/8 inch thick.

C Flute –

C Flute in Corrugated box is most commonly used in the shipping industry.

Around 80% of the Corrugated box used are made up of C flute.

C Flute is used in packaging of glass materials and dairy products.

C Flute has good stack strength and excellent crushing strength and high acceptance to printing.

C Flute Contains 39 flutes per foot and 3/16 inch thick.

E Flute –

E flute in Corrugated box has more crushing resistance and comparatively flat surface for printing operations.

E Flute is thinner and provide better cushioning and has a flat surface resulting in being used in

E Flute is more preferable over conventional cardboard box for packaging of fragile glass products and ceramic products due to its properties of providing thinner and flat surface and better cushioning.

E Flute contains 90 flutes per foot and 1/16 inch thick.

F Flute –

F Flute in Corrugated box has more flutes than E Flute, making it stiffer and flatter.

F Flute is commonly used in cosmetics, pharmaceutical products and other delicate products packaging.

F Flute contains 125 flutes per foot and 1/32 inch thick.

No responses yet